1. APPLICATION:

Tungsten carbide roll ring is applied to high-speed wire rod mill.

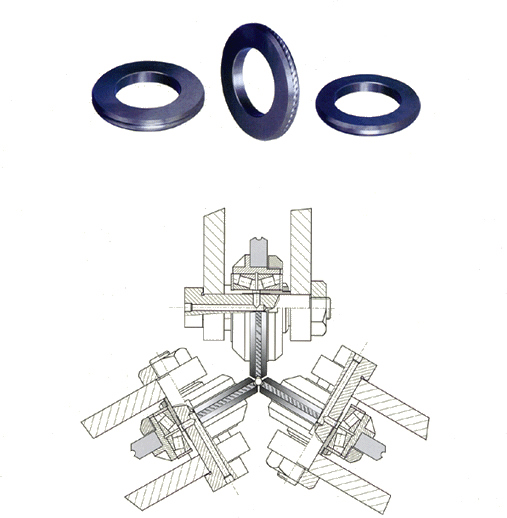

2. Product series

2.1. Flat roll series

2.2 Grooved roll series

2.3. Ragged roll series

3. Product feature

3.1. Advanced processes

3.2. Stable mechanical property

3.3. High resistance to impact, hot crack and corrosion

4. Process

4.1. World-class-advanced paraffin process and spray drying grain-making process (see. Picture 1),

which property of grain can be ensured.

4.2. 500-ton alpha press imported form USA.

4.3. Hot isostatic press.

4.4. L-HIR low-voltage sintering furnace, which was newly imported so as to highly improve internal

structure of raw material of roll ring.

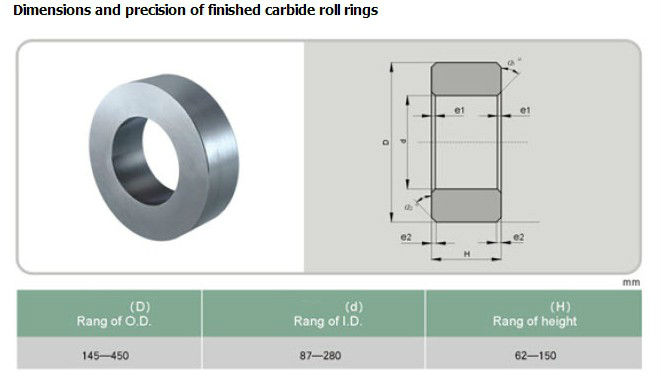

4.5. D403 grinding machine specially used for roll ring (see. Picture 5) as well as finisher specially used

grooving and shaping from Germany can ensure the dimension precision of finish-grinding of roll

ring.

5.Series and Application

Series | Intermediate stand | Prefinishing | Finishing | ||||||||

Stand | Stand | ||||||||||

16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | ||

ZY27, ZY28, ZY29 | ● | ○ | ○ | ○ | |||||||

ZY30, ZY30A | ○ | ○ | |||||||||

ZY31, ZY31A | ● | ● | ● | ● | |||||||

ZY32, ZY32A | ○ | ○ | ● | ● | ● | ● | ● | ● | |||

ZY33, ZY34A | ● | ● | |||||||||

ZY35A, ZY36A | ● | ● | |||||||||

Note:A: pure Co base

●: first selection

○: secondary selection

○: supporting roll

6.Series and Technical Data

Series | Chemical composition | Density g/cm3 | WC grain μm | Hardness HRA | Bending strength N/mm2 | Compression strength KN/mm2 | Elastic modulus KN/mm2 | Hammer impact J | Poisson's ratio | Resistivity μΩ.cm | Thermal Conductivity W/(m.k) | Average coefficient of heat expansion 10-6/k | |

WC | Co Ni | ||||||||||||

ZY27 | 70 | 30 | 12.7 | 2-4 | ≥ 81.0 | ≥ 2300 | ≥ 3.0 | 420 | 3.0 | 0.26 | 16 | 60 | 5.8~7.0 |

ZY28 | 75 | 25 | 13.15 | 2-4 | ≥ 82.0 | ≥ 2300 | ≥ 3.1 | 430 | 2.8 | 0.25 | 16 | 60 | 5.5~6.5 |

ZY29 | 78 | 22 | 13.35 | 2-4 | ≥ 82.5 | ≥ 2300 | ≥ 3.1 | 440 | 2.6 | 0.24 | 16 | 70 | 5.5~6.5 |

ZY30 | 80 | 20 | 13.5 | 2-4 | ≥ 83.5 | ≥ 2450 | ≥ 3.3 | 450 | 2.4 | 0.24 | 16 | 70 | 5.2~6.0 |

ZY30A | 80 | 20 | 13.5 | 2-4 | ≥ 84.0 | ≥ 2450 | ≥ 3.5 | 480 | 2.4 | 0.24 | 16 | 70 | 5.2~6.0 |

ZY31 | 82 | 18 | 13.6 | 2-4 | ≥ 83.5 | ≥ 2450 | ≥ 3.6 | 450 | 2.2 | 0.23 | 17 | 96 | 5.0~5.8 |

ZY31A | 82 | 18 | 13.6 | 2-4 | ≥ 84.0 | ≥ 2450 | ≥ 3.7 | 480 | 2.2 | 0.23 | 17 | 90 | 5.0~5.8 |

ZY32 | 85 | 15 | 13.95 | 2-4 | ≥ 84.5 | ≥ 2500 | ≥ 3.8 | 500 | 2.0 | 0.23 | 17 | 100 | 5.0~5.8 |

ZY32A | 85 | 15 | 13.95 | 2-4 | ≥ 85.5 | ≥ 2500 | ≥ 4.0 | 530 | 2.0 | 0.23 | 17 | 100 | 5.0~5.8 |

ZY33 | 85 | 15 | 13.95 | 2-4 | ≥ 85.0 | ≥ 2500 | ≥ 3.8 | 530 | 2.0 | 0.22 | 17 | 100 | 5.0~5.8 |

ZY34A | 87 | 13 | 14.10 | 2-4 | ≥ 86.0 | ≥ 2400 | ≥ 3.8 | 550 | 1.8 | 0.22 | 17 | 100 | 4.8~5.6 |

ZY35A | 90 | 10 | 14.35 | 2-4 | ≥ 87.0 | ≥ 2300 | ≥ 4.0 | 550 | 1.6 | 0.21 | 17 | 100 | 4.8~5.6 |

ZY36A | 94 | 6 | 14.95 | 2-4 | ≥ 88.0 | ≥ 2100 | ≥ 4.2 | 600 | 1.6 | 0.21 | 17 | 100 | 4.5~5.4 |