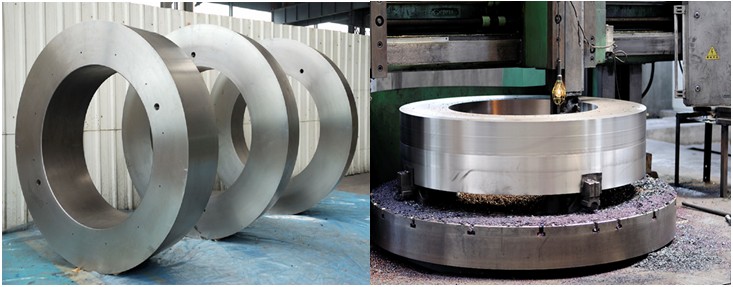

TYPE: CAST STEEL RING

1. ALLOY CAST STEEL ROLL

◆SUMMARY They are made of high quality steel melted with electric arc furnace (EAF) and finished with advanced foundry and heat treatment technologies. Roll barrel is mainly composed of pearlite (or temper sorbite) in the microstructure. |

◆ADVANTAGE

◇ High tensile strength

◇ High wearability

◇ Good toughness

◇ Excellent resistance to fire crack

◆MECHANICAL PROPERTIES & APPLICATION

Symbol | Hardness (HS) | Tensile Strength (MPa) | Elongation (%) | Application |

AS60A | 45-55 | >700 | >8 | Bloomer and slab mills, rougher of large section mills |

AS70A | 34-44 | >680 | >7 | Rougher of section, bar and rod mills Rougher of narrow strip mills Vertical scale-breaking rolls. |

AS70B | 36-46 | >680 | >7 | |

AS75 | 36-46 | >680 | >6 | |

AS75A | 35-55 | >800 | >7 | |

AS75B | 40-60 | >800 | >7 | Bloomer and slab mills Back-up rolls of narrow strip mills. |

2. ADAMITE ROLLS

◆SUMMARY Adamite is one type of special material with elements such as Ni, Cr, Mo etc. Special heat treatment is used. Its mechanical properties and carbon content is between steel and iron. It is shaped by Centrifugal Casting Machine, or by gravity casting. |

◆ADVANTAGE

◇ No hardness gradient in the working layer

◇ High wearability

◇ Good toughness

◇ Good resistance to fire crack

◆APPLICATION

◇ For hot strip rolling line: Rougher and front stands of the finishers.

◇ For bar and wire rolling line: Rougher, intermediate stands and pre-finishing stands.

◇ For universal mills and cantilever mills: Roll rings and roll sleeves.

◆MECHANICAL PROPERTIES

※1 Tensile strength

Symbol | Hardness (HS) | TS※1 (MPa) | Elongation (%) | Application |

AD140A | 35-50 | 500~800 | ≥ 1.0 | Bloomer, slab mill, rougher with large section |

AD160A | 40-60 | 500~800 | ≥ 1.0 | Rougher, bar and rod mill narrow strip mill vertical scale-breaking rolls. |

AD180A-AD220 | 50-60 | 450~700 | ≥ 0.5 | |

AD GT | 55-65 | 690~850 | ≥ 0.5 | Finish stands with large section Roll rings and roll sleeves. |

3. GRAPHITE STEEL ROLLS

◆SUMMARY It is one kind of special material with a small amount of graphite in its microstructure. Its mechanical properties and carbon content are between steel and iron. It is shaped by gravity casting. |

◆ADVANTAGE

◇ No hardness gradient in the working layer

◇ High wearability

◇ Good toughness

◇ Excellent resistance to fire crack - Better than Adamite rolls

◇ Preventing oxidized scales from adhering

◆APPLICATION

◇ Bloomer or rougher for bar , rod and hot strip mills

◇ Roll rings and roll sleeves for universal mills

◆MECHANICAL PROPERTIES

Symbol | Hardness (HS) | Tensile strength (MPa) | Elongation (%) |

GS140A | 36-46 | 540-800 | ≥ 1.0 |

GS160A | 40-60 | 500-750 | ≥ 1.0 |

4. HIGH SPEED STEEL ROLLS

◆SUMMARY The working layer of HSS rolls are made of alloy V, W, Nb and Mo, and shaped in Centrifugal Casting Machine, with spheroidal graphite cast iron in its core. |

◆ADVANTAGE

HIGH HARDNESS

The hardness of roll working layer to reach as high as 80-85HSC with the control of element composition and heat treatment.

GOOD WEAR RESISTANCE AT HIGH TEMPERATURE

It ensures good wear resistance at high temperature and uniform wear in the roll passes, as the important metal elements are uniformly distributed in the martensitic structure, such as V (Vanadium), W (Tungsten), Nb (Niobium) and Mo (Molybdenum).

IMPROVEMENT OF SURFACE QUALITY OF ROLLED PIECE

◆APPLICATION

◇ Work rolls of finishing stands for hot strip mills

◇ Work rolls of finishing stands for hot bar mills

◇ Pre-finishing stands for high-speed wire mills

◆MECHANICAL PROPERTIES

Item Position | Hardness (HS) | Tensile strength (MPa) | Modulus of elasticity (× 103MPa) |

Work layer | 80-85 | 700~900 | 210~240 |

core | - | ≥ 400 | 140~180 |